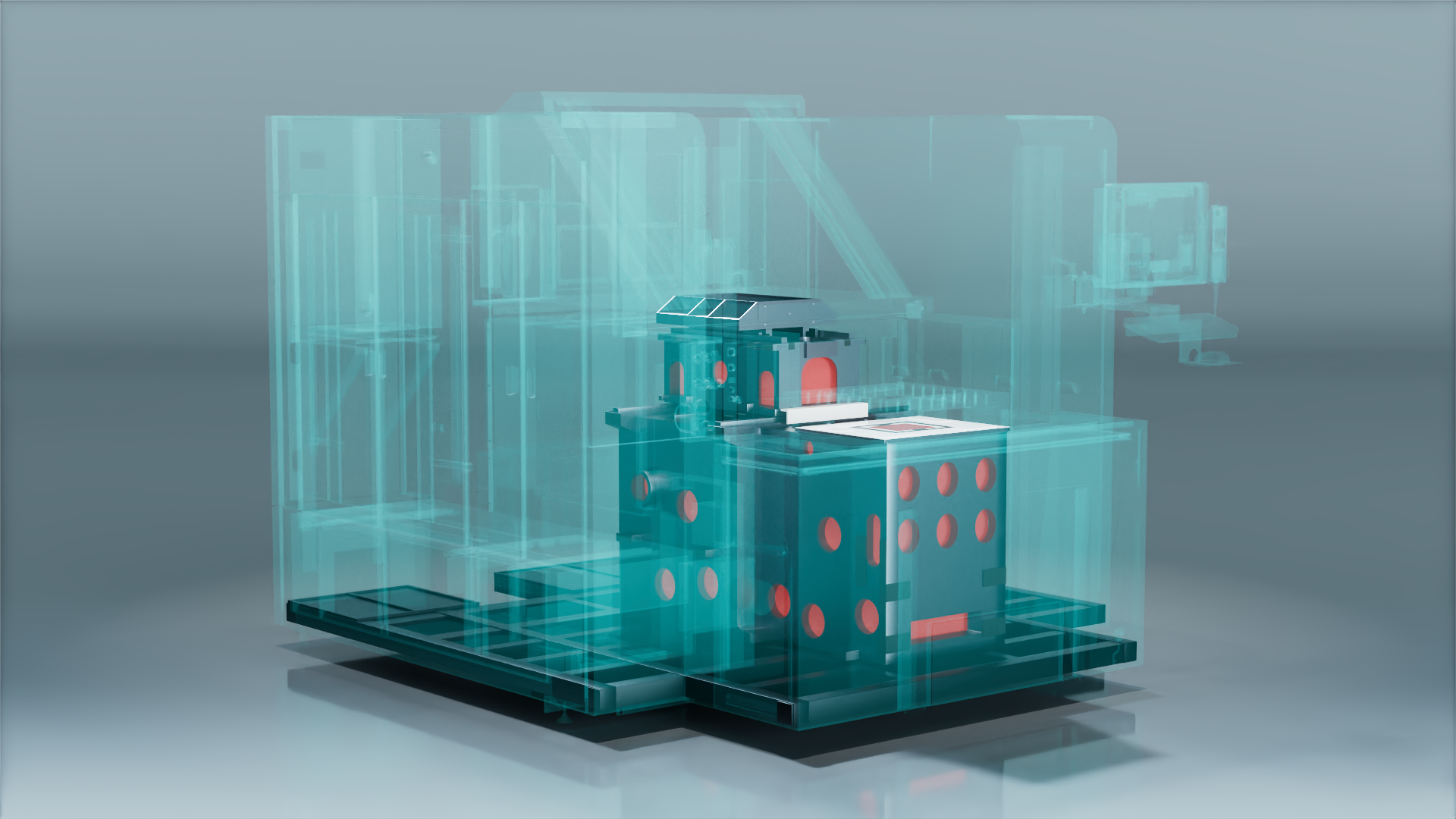

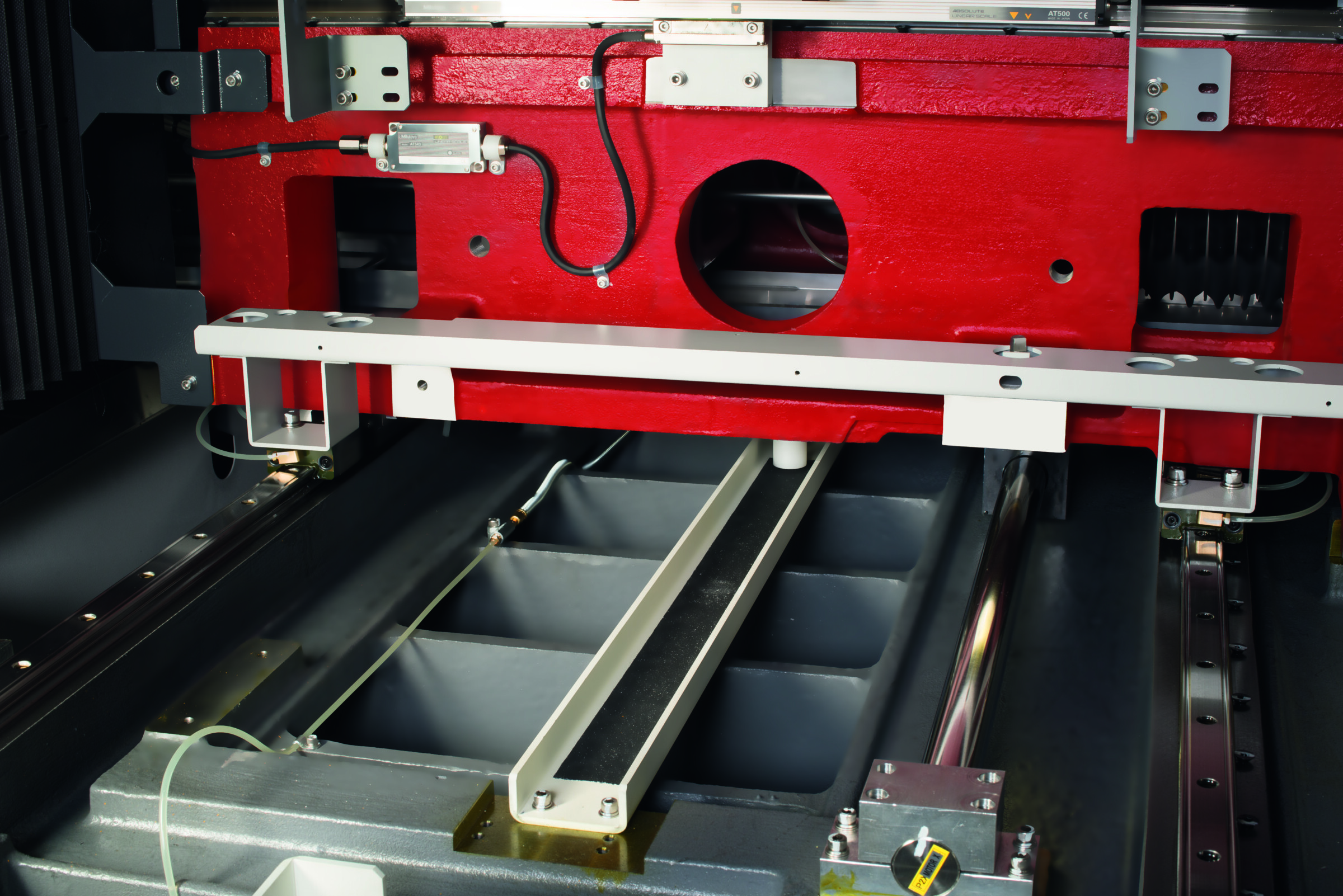

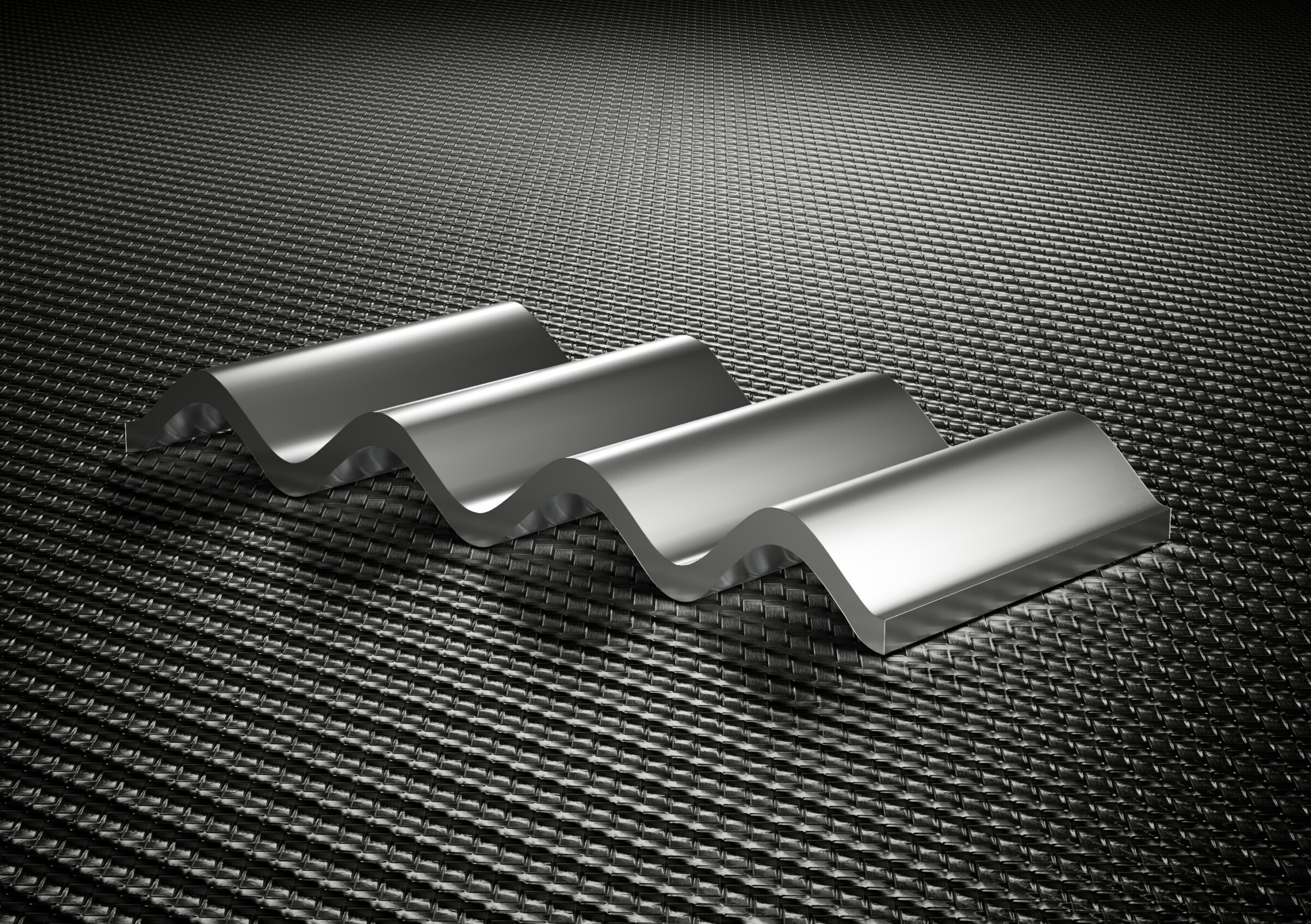

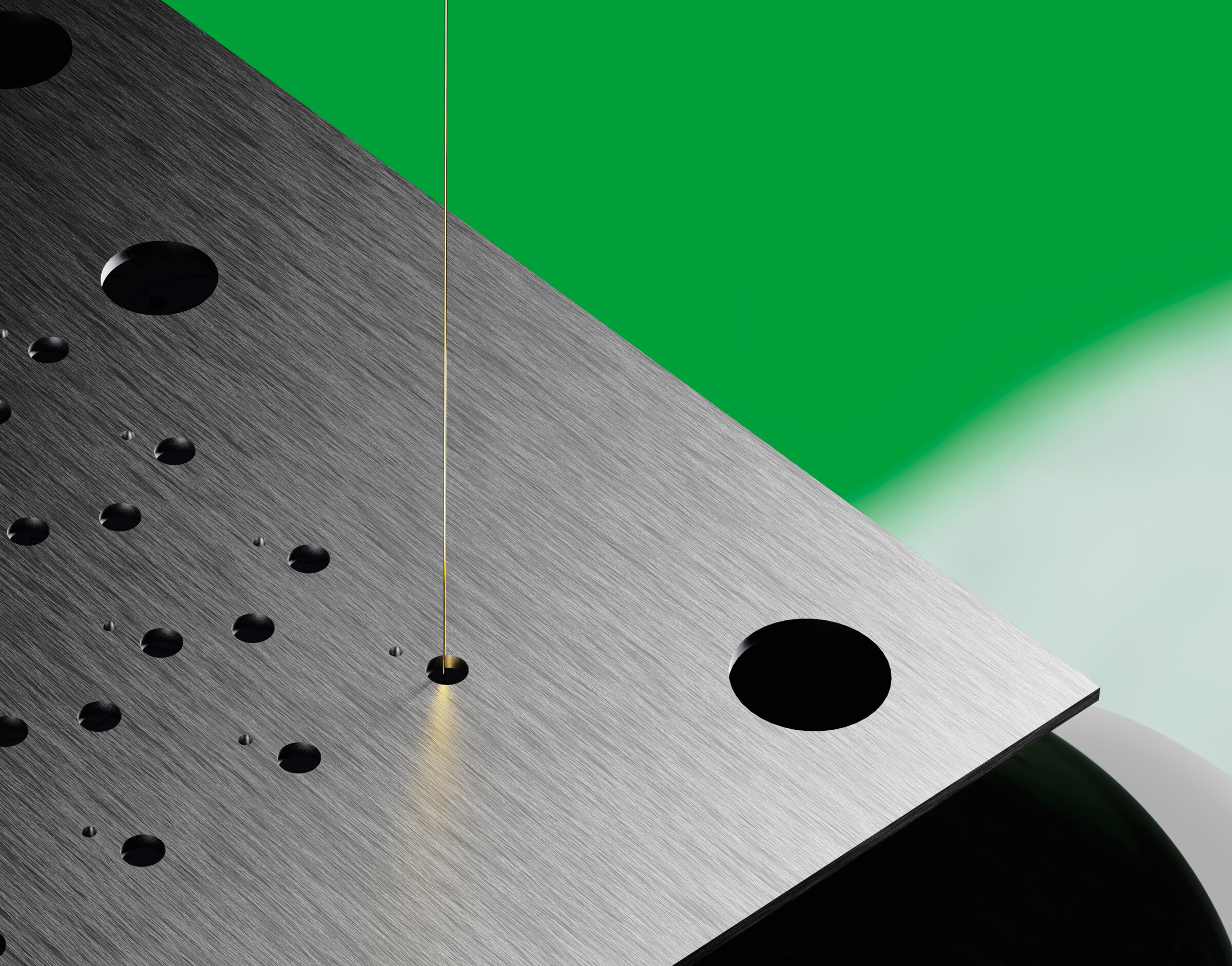

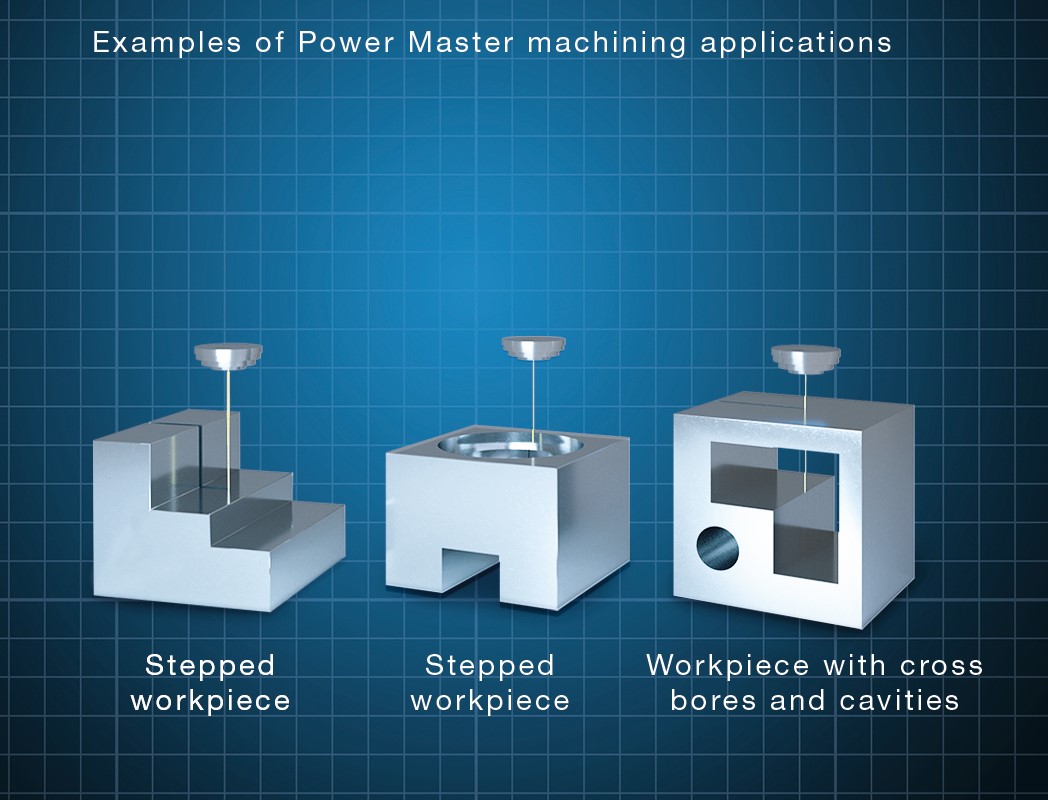

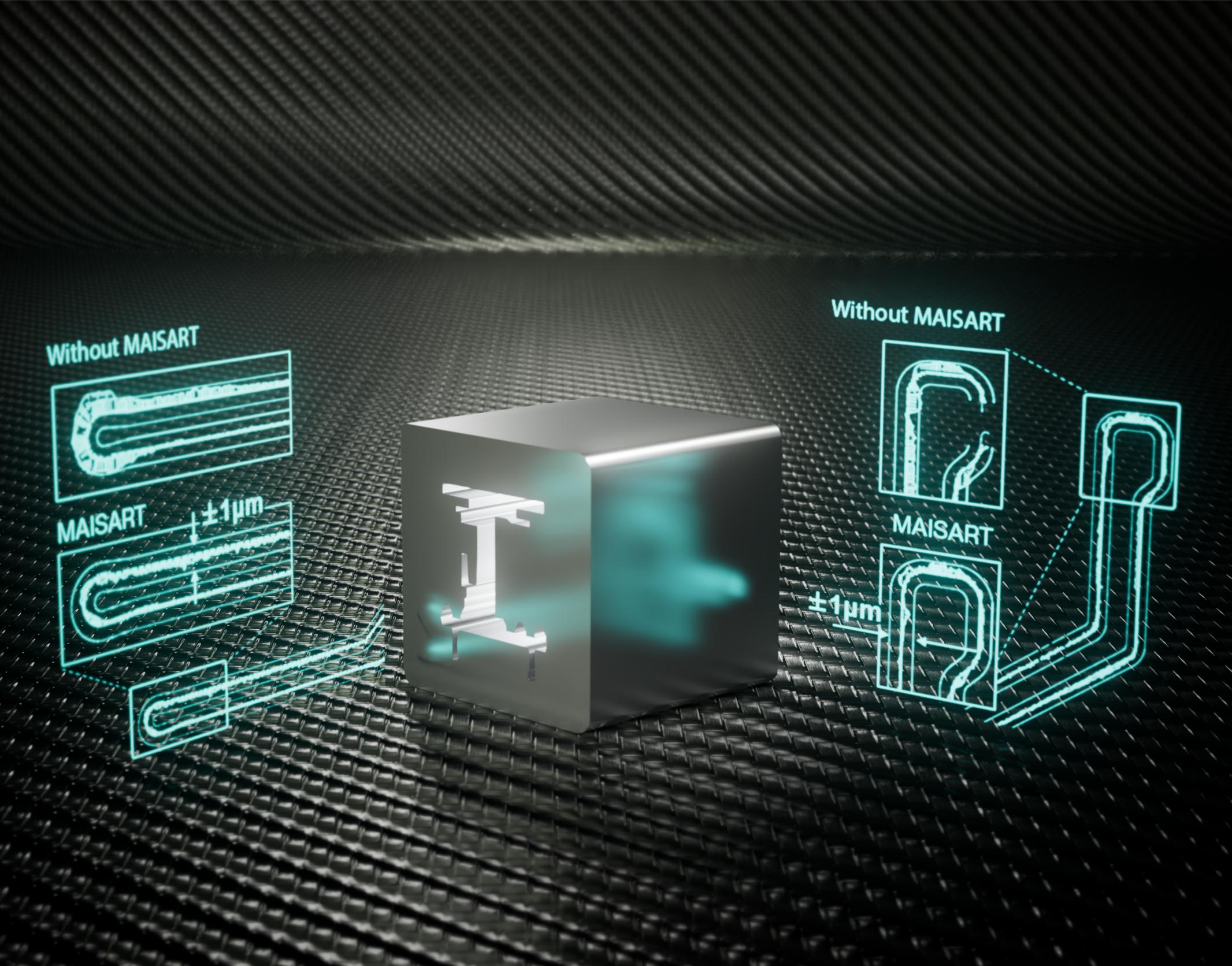

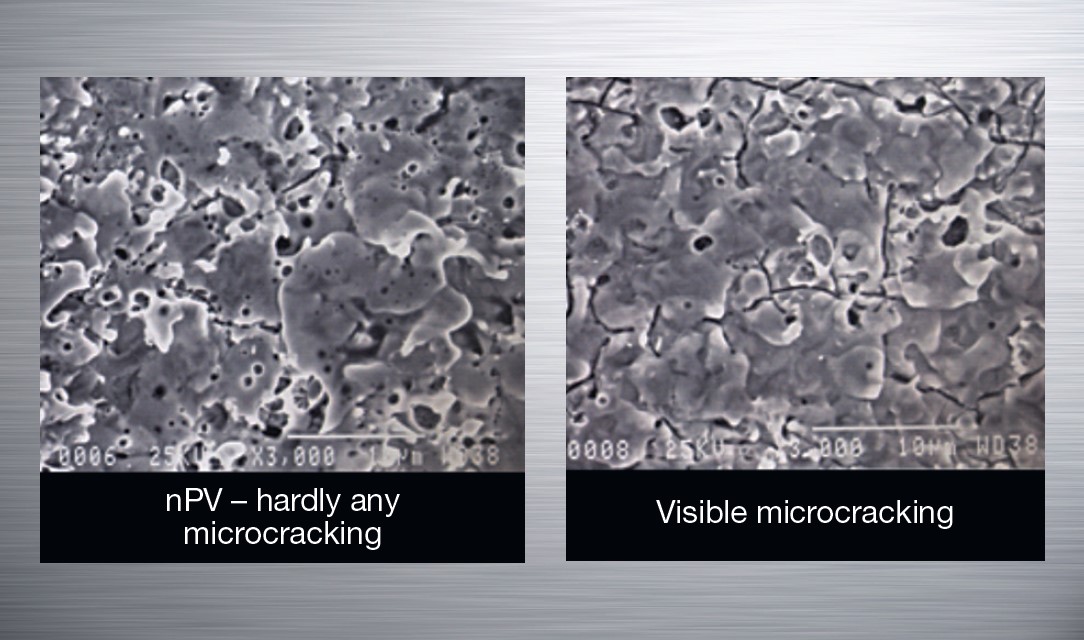

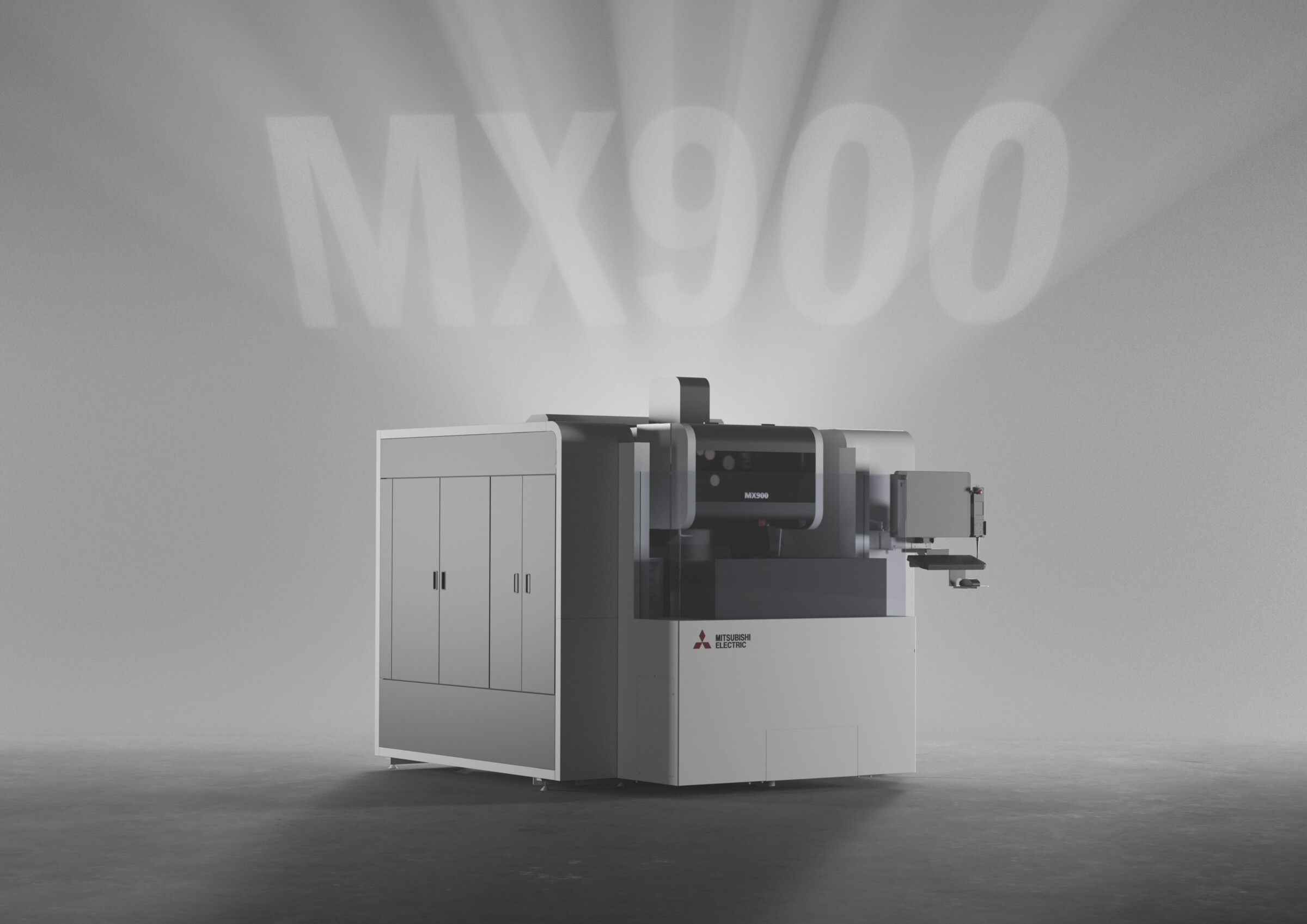

Die MX900 ist die modernste Lösung von Mitsubishi Electric für die Hochleistungs-Drahterodierbearbeitung in Öl. Die MX900 wurde entwickelt, um die anspruchsvollsten Anforderungen zu erfüllen, und bietet außergewöhnliche Präzision, glattere Oberflächen und verbesserte Effizienz bei jedem Schnitt. Mit bahnbrechender Technologie und überlegener Steuerung ist sie die ultimative Maschine für Branchen, die makellose Präzision erfordern.

| X | Y | Z | ||

|---|---|---|---|---|

| MX900 Series | 300 | 300 | 120 |

| Machine | MX900 | |||

|---|---|---|---|---|

| Travel (X / Y / Z) in mm | 300 / 300 / 120 | |||

| Travel (U / V) in mm | (+/- 35) | |||

| Taper angle (workpiece height) in °/mm | Max. 15° | |||

| Max. workpiece dimensions (W x D x H) in mm | 500 x 500 x 100 | |||

| Max. workpiece weight in kg | 300 | |||

| Table dimensions (W x D) in mm | 560 x 505 | |||

| Table layout | Hardened 4-sided table | |||

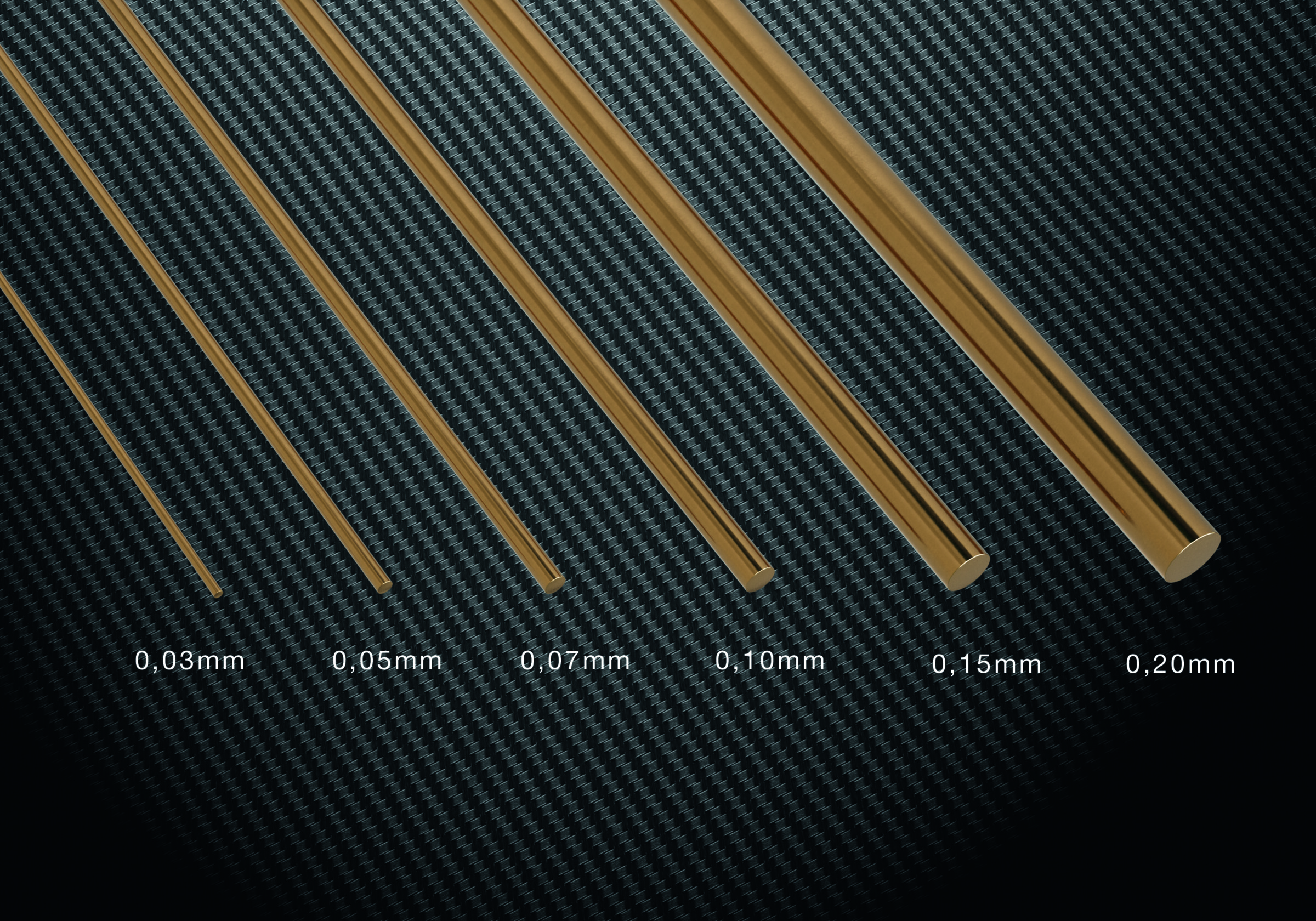

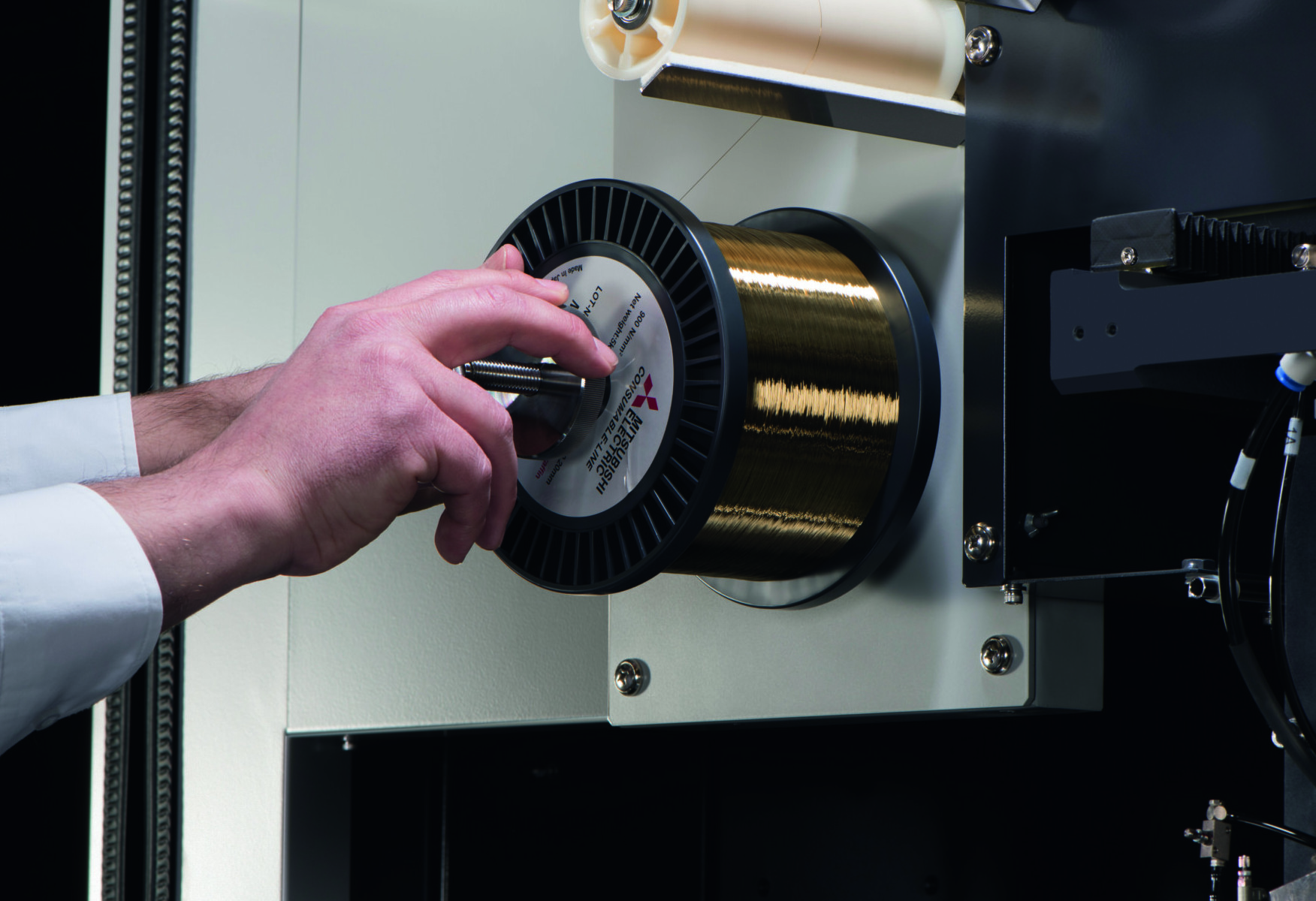

| Possible wire diameters in mm | 0.05 – 0.2 | |||

| Wire spool capacity in kg | 10 | |||

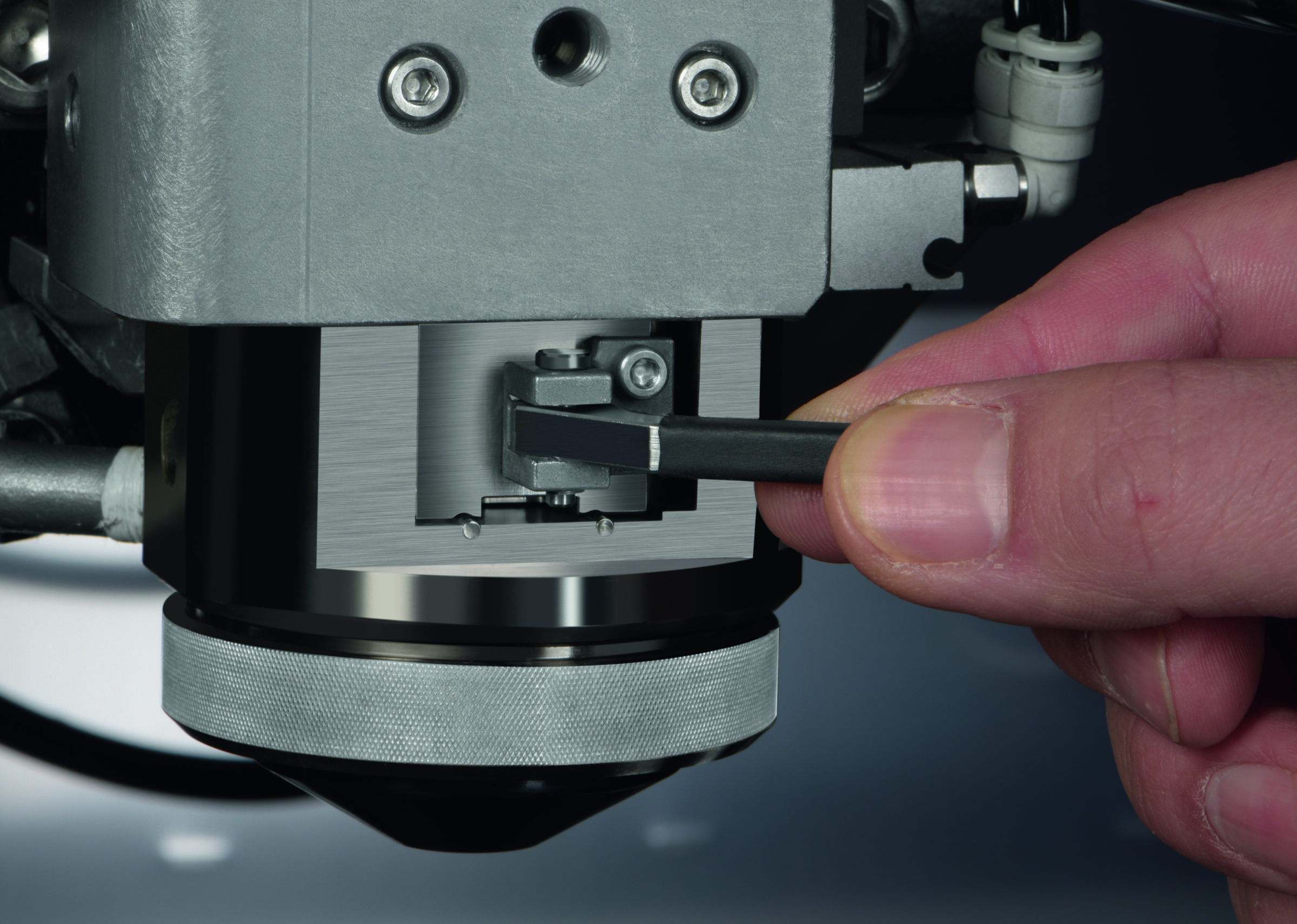

| Automatic wire threader / wire chopper | Yes | |||

| Overall dimensions (W x D x H) in mm | 2335 x 2965 x 2203 | |||

| Machine weight in kg | 3400 | |||

| Mains voltage | 3-phase 400 V/AC ± 10%, 50/60 Hz, 13 kVA | |||

| Filter system | MX900 | |||

|---|---|---|---|---|

| Tank capacity in l | 325 (Initial filling 350 l) | |||

| Filter particle size in µm / filter elements | 3/2 | |||

| Temperature control | Dielectric cooling unit | |||

| Weight (dry) in kg | 600 | |||

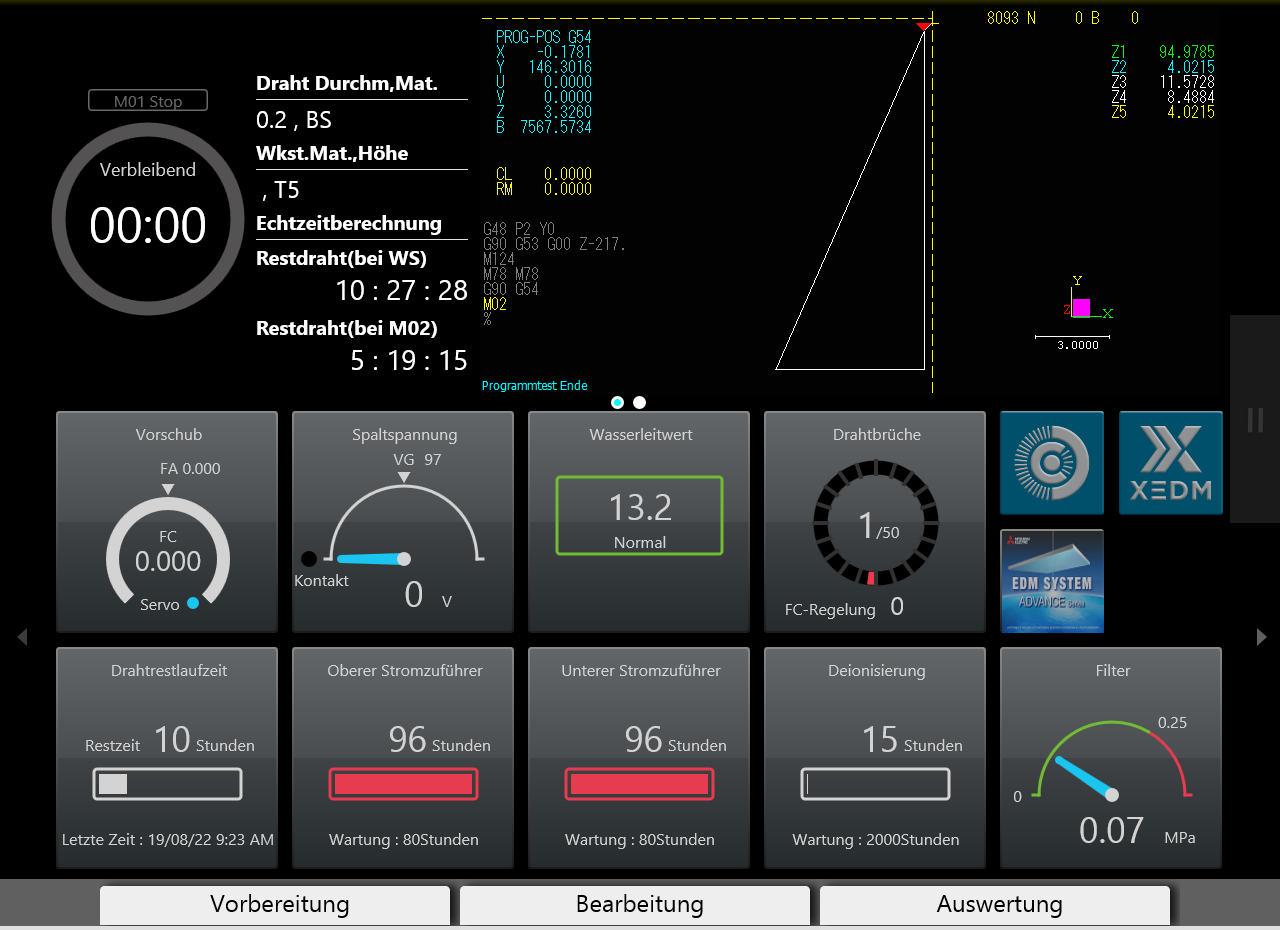

| Control | MX900 | |||

|---|---|---|---|---|

| Input method | Keyboard, USB flash drive, Ethernet, 19” touchscreen | |||

| Control system | 19“ touchscreen / CNC, closed circuit | |||

| Min. command step (X / Y / Z / U / V) in µm | 0.1 | |||

| Min. axis resolution in µm | 0.05 | |||

| Equipment | MX900 | |||

|---|---|---|---|---|

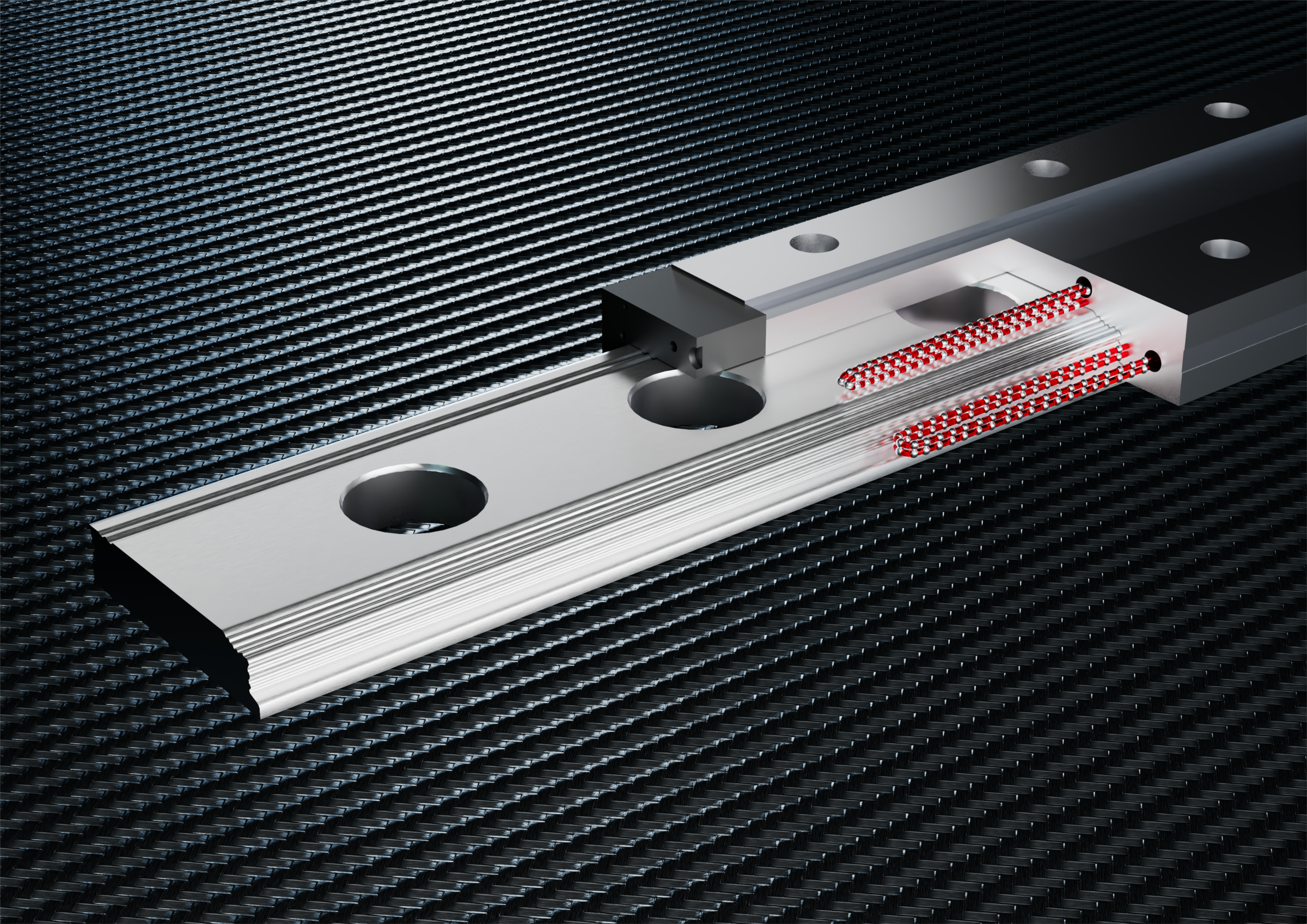

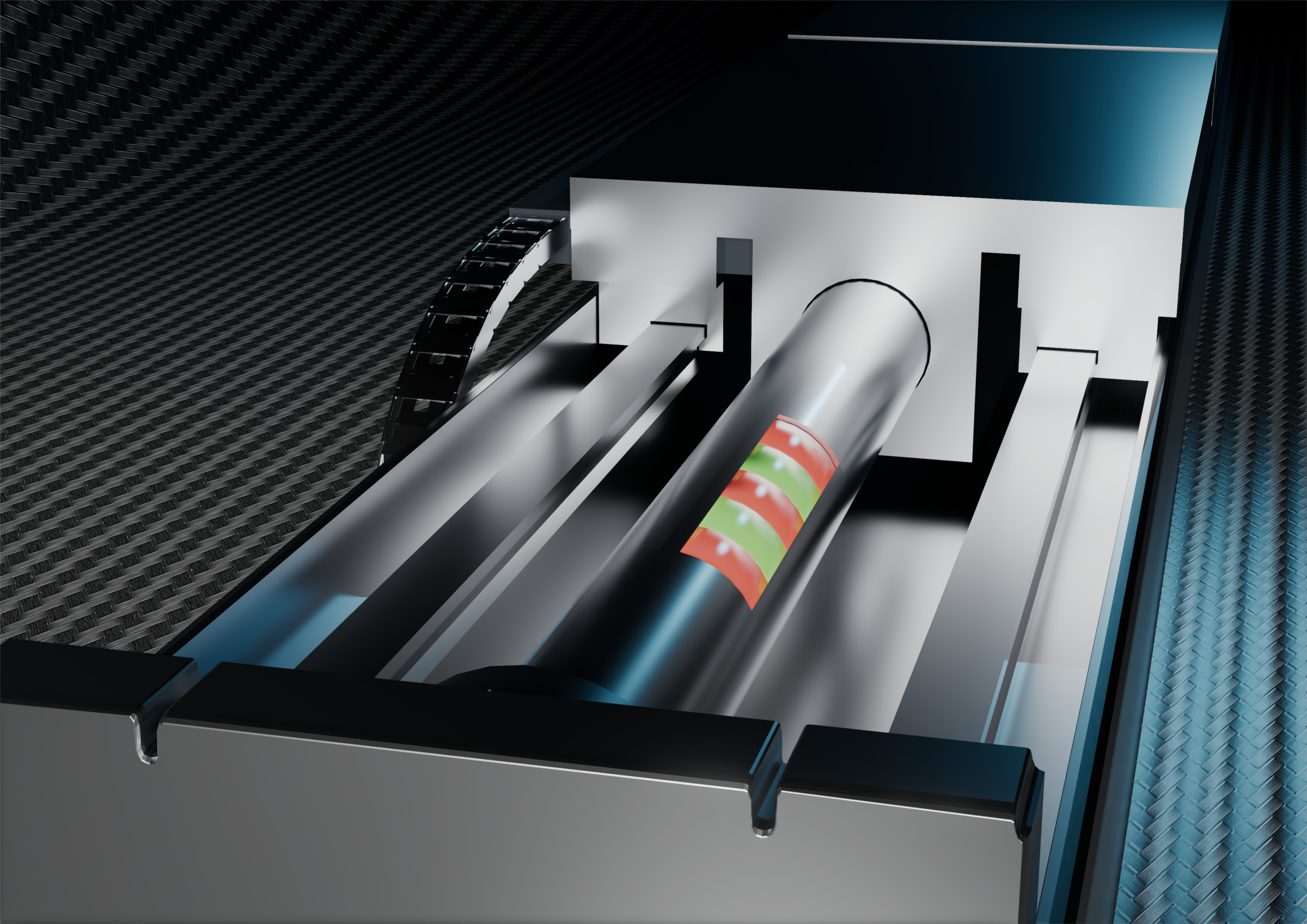

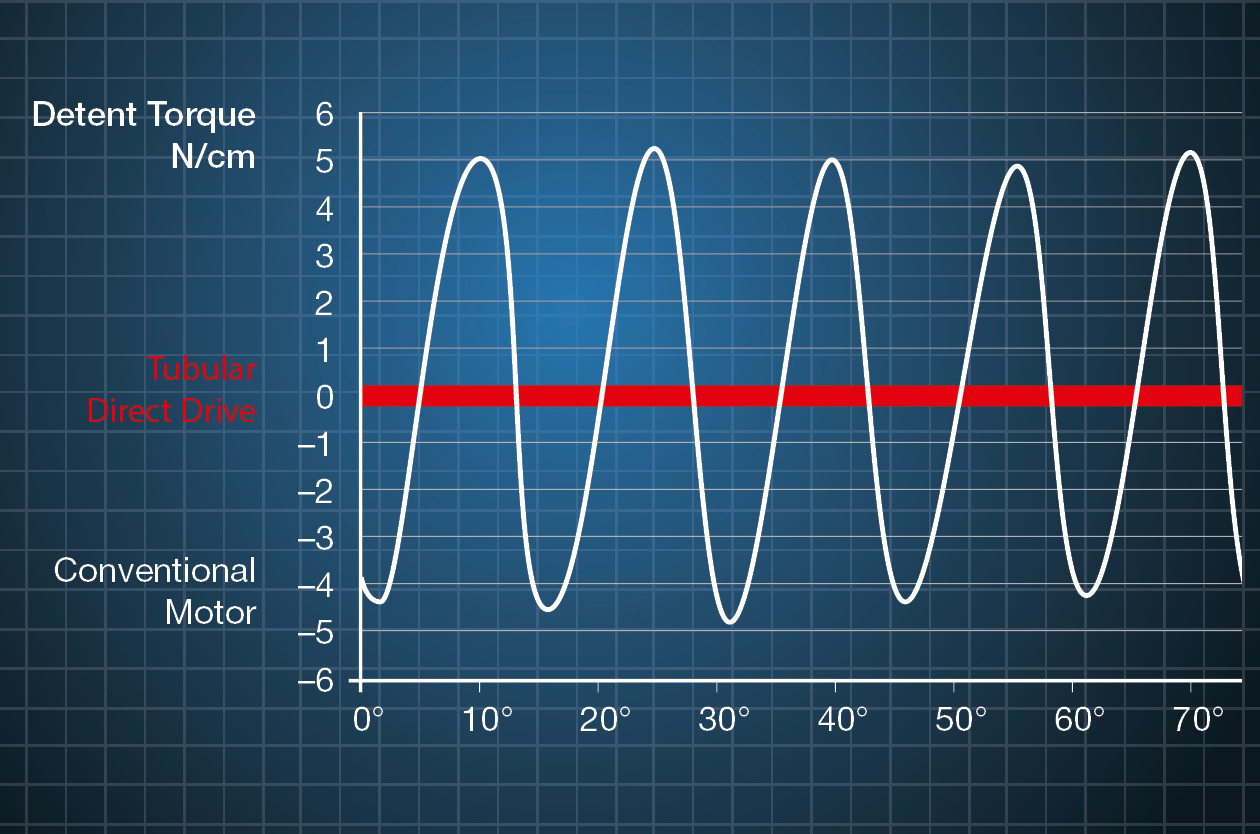

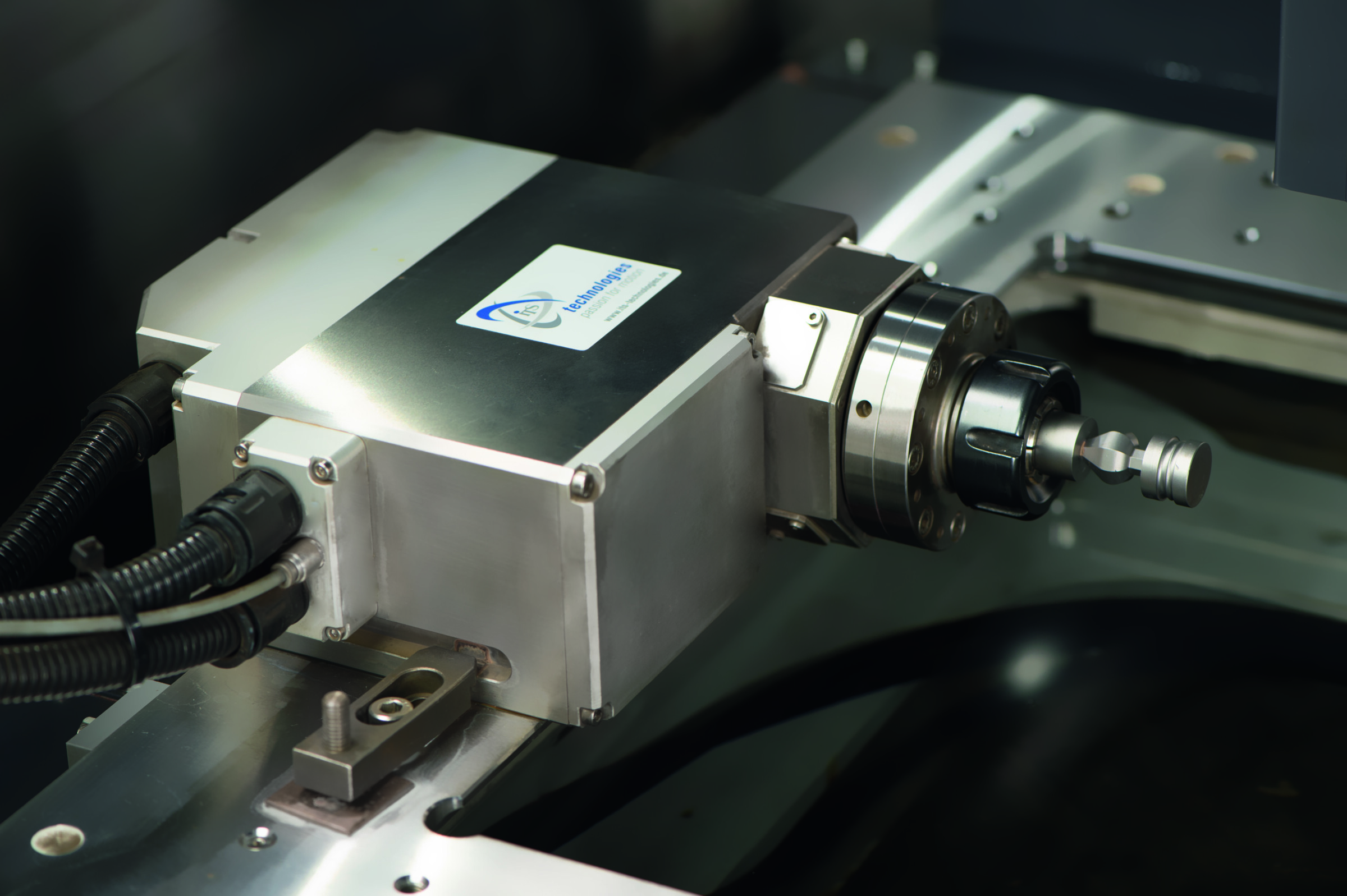

| Tubular Shaft Drives with linear scales (X / Y / U / V) | Yes | |||

| Control M800 with 19” full-touch monitor | Yes | |||

| Hand pilot with configurable LCD monitor | Yes | |||

| Automatic vertical front door | Yes | |||

| Digital AE II generator | Yes | |||

| Hardened 4-side frame table | Yes | |||

| Ethernet/DNC/FTP | Yes | |||

| McAfee AntiVirus embedded | Yes | |||

| Sleep mode | Yes | |||

| Optional Hardware | MX900 | |||

|---|---|---|---|---|

| Thin wire specification 0.03 mm | Optional | |||

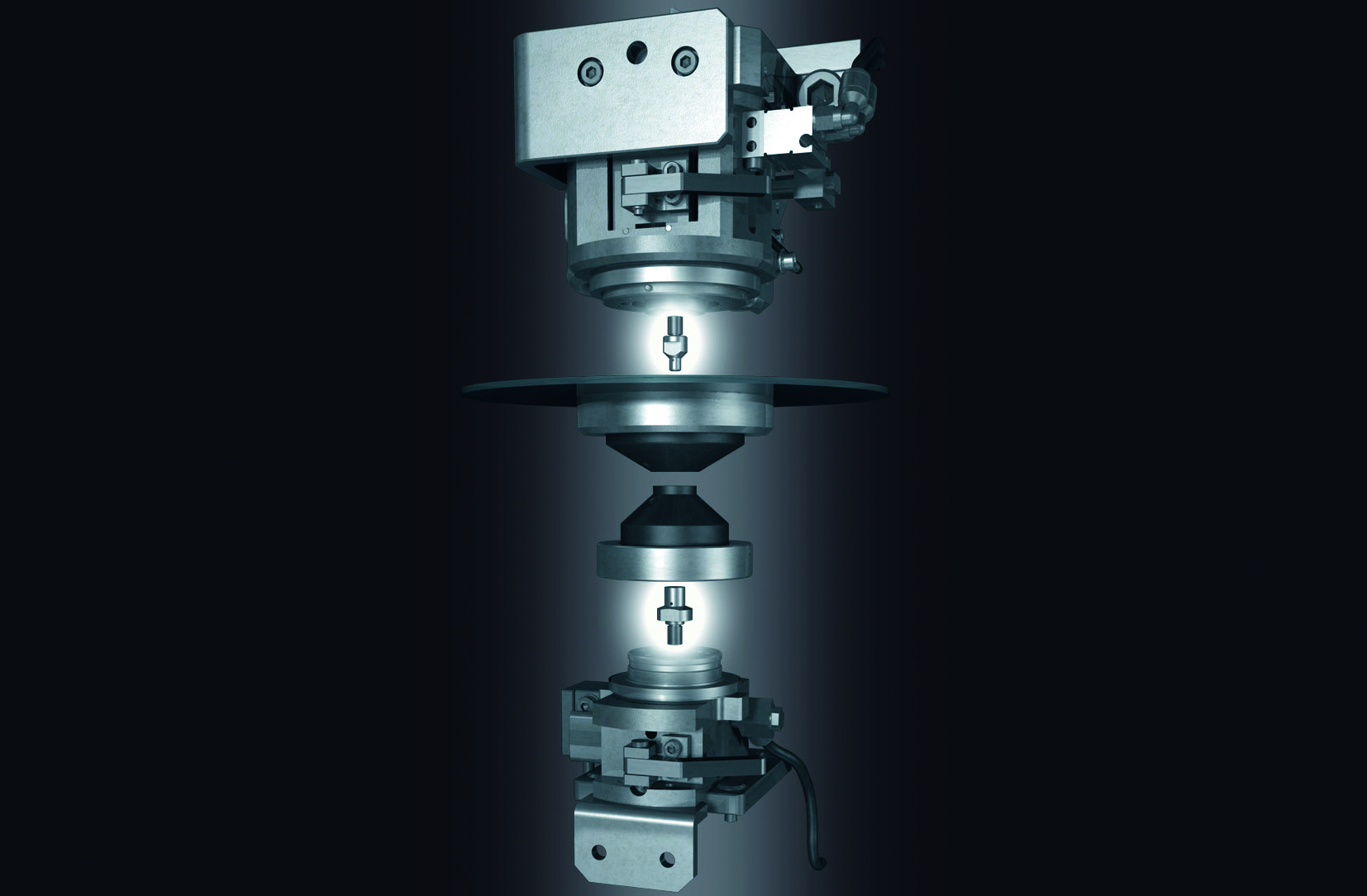

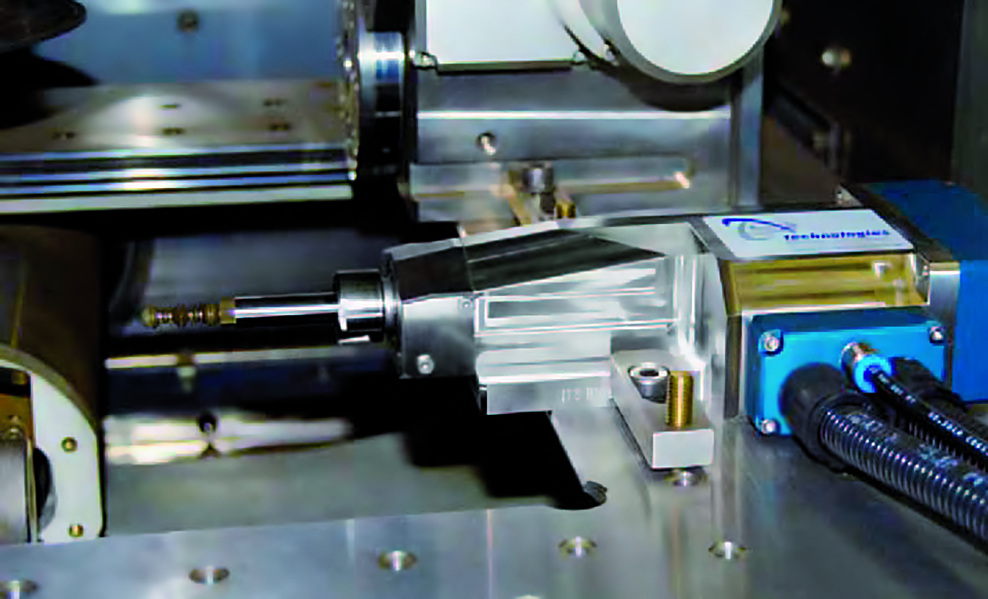

| Angle Master Advance II – basic kit incl. aligning device | Optional | |||

| Angle Master advance II – Wire guide kit | Optional | |||

| External signal output with relay board | Optional | |||

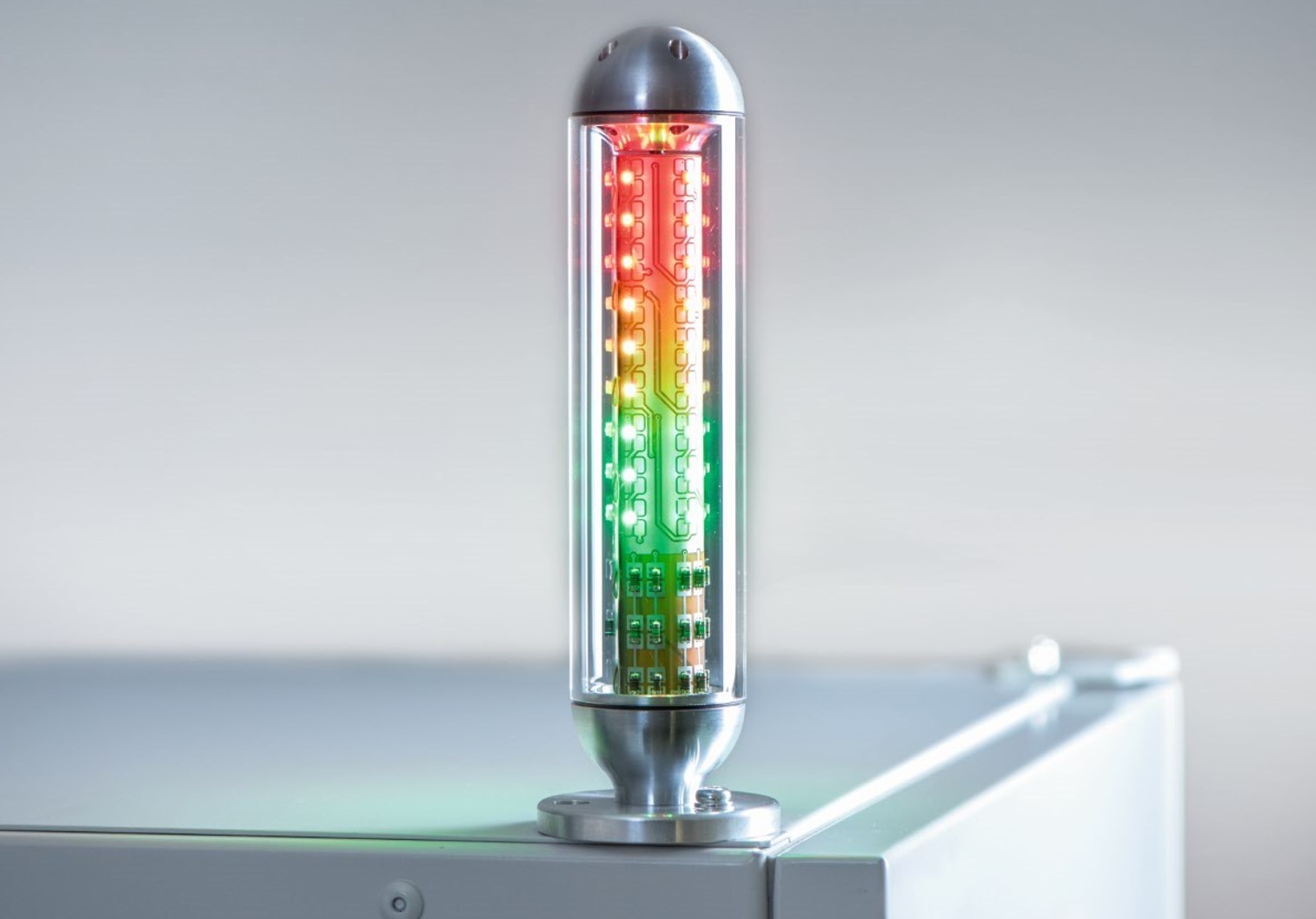

| Tricolour status lamp | Optional | |||

| Automatic Renishaw probe | Optional | |||

| ERGO-LUX LED floodlight | Optional | |||

| Renishaw touch probe | Optional | |||

| Additional axes / rotational axis | Optional | |||

| Optional Tools | MX900 | |||

|---|---|---|---|---|

| mcAnywhere Service / Live Service | Yes | |||

| mcAnywhere Control / mcAnywhere Control light | Optional | |||

| mcAnywhere Contact / mcAnywhere Contact light | Optional/Yes | |||

| Tool package / automation solutions | Optional | |||

| Generator | MX900 | |||

|---|---|---|---|---|

| Power supply unit | Regenerative transistor pulse type | |||

| Cooling method | Fully sealed / indirect air cooling | |||

| Max. output current in A | 50 | |||

| Dimensions (W x D x H) in mm | Integrated in the machine module | |||

| Weight in kg | 600 | |||

Felder die mit einem * markiert sind, sind Pflichtfelder.

Mitsubishi Electric Europe B.V.

Deutsche Niederlassung

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Vertrieb

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Anwendungen

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Ersatzteile

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com